- Contact Person : Mr. Ruan Hongfei

- Company Name : Shanghai Huanying Paint Co., Ltd.

- Tel : 86-21-69152306

- Fax : 86-21-69152309

- Address : Shanghai,Shanghai,No.58 Chenbao Road, Malu town ,jiading district,Shanghai

- Country/Region : China

- Zip : 201801

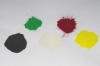

Colorful powder coating

Colorful powder coating 1 . When turning Indian workpiece and spray the powder of corresponding model , make it solidify a little excessively . Recommend temperature< workpiece temperature> 25 minutes of 180°C and 18 minutes of 190°C 2 . According to the width of workpiece surface , select the paper roll of suitable width 3 . The running water even spray is paste surface 4 . Check the quality that will paste paper , whether leakage prints or has no the place of applying glue . The paper of qualified uses sponge according to the direction of figure , roll or soft hair rolls fast rub paste on workpiece , had better not make efforts to pull show paper , make its excessiveness be unholded , should follow its mature , avoid that in bake process , paper is heated to contract , break away from coating . May also use other methods . While water doesn`t permeate paper completely , uses sharp blade , cuts extra paper , and on workpiece joint gap , trademark , passage as well as all protuberant things , the paper that covers is cut open thoroughly with sharp blade along the protuberant thing edge and place of joint gap , compress tightly in order to avoid paper is heated contraction , pull paper , make this low place not to color , under paper if has bubble , bubble makes apply steel needly from paper when wrinkling to puncture on edge , drives out water and air , makes paper paste tightly on film , on the workpiece that pastes paper , discovery has concave next lacation should spray water on paper , let paper permeate fully , make efforts to compress tightly , attention : the edge of paper should compress tightly 5 . The workpiece that pastes , when water doesn`t do , hang when since go to type bake to solidify stove production line go up , while hanging , it is meshed to must be careful in order to avoid that touching , stroke meshed turn Indian paper . Before heat able brick bed , check again whether have meshed the paper in carrying process carelessness touched if having , applying the paper larger than meshed piece , slightly after , spray water , according to the same lines direction , paste on it , restore . 6 . Enter oven bake , recommend temperature : 20 minutes of 160°C , 12 minutes of 180°C . It is greater that this bake condition gets the factor influences such as oven form and working form . Customer should toast technology according to specific condition through testing to determine . The cdor of this product gets bake condition , have greater influence , usually temperature is high and color changes weak ; temperature is low and color changes deep . At the same time , temperature is too high , will make paper change crispy , up to carbonization , is hard to uncover , spray water and wait a while to uncover again take off . 7 . Uncovering turning Indian paper take off , if mucilage seal is too obvious , may clean with warm towel ; edge , don `t uncover next paper well , also rub with warm towel . 8 . Pay attention while using this technology paper . This paper in use , prevent contacting with paper . Once contact water , the paper of finished product will glue knot , can not use , can `t also contact sundry goods . Normally , storing to put should prevent damp , is water-vapor proof , guard against rain . 9 . Paper is not good base and the reason of uncovering powder is solidified not enough , make efferts when pasting exceptional , base powder is solidified , rear film layer surface had been polished , causes rough , lose the neat smooth etc , of original coat . decided according to the resin type of product , ask reference product specifidy follows the explanation attached . 10 . Steel system turns the Indian wooden veins cupboard of official business . 11 . Steel system turns Indian wooden veins burglar proof door 12 . Turn Indian aluminum profile sample plate |

Colorful powder coating